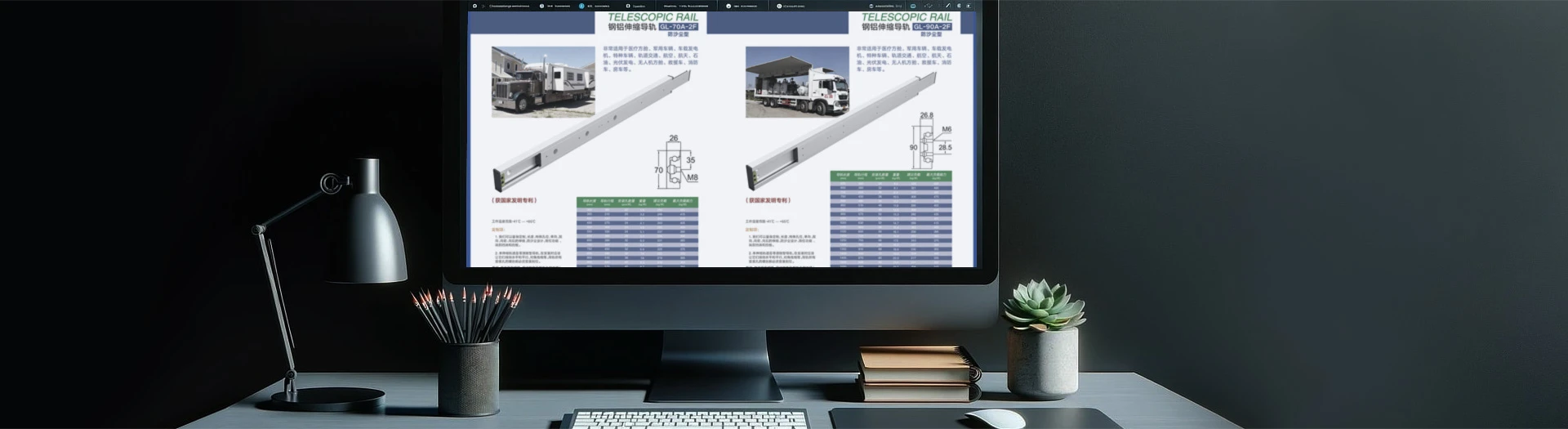

Industrial applications of steel and aluminum telescopic guide rails

In modern industrial production and across numerous mechanical equipment sectors, steel-aluminum telescopic guides play a crucial role. Like a silent, behind-the-scenes hero, they often remain out of the spotlight, yet their unique performance and advantages support the precise operation of various types of equipment and contribute to the efficient development of the industry.

The name of the steel-aluminum telescopic guide reveals its primary components: steel and aluminum. This ingenious combination blends the excellent properties of both metals. Steel, renowned for its exceptional strength and rigidity, can withstand significant loads without easily deforming, providing a stable framework for the guide rail. Aluminum, on the other hand, offers the added benefit of lightness. Its low density allows the entire guide rail to maintain strength while minimizing its weight, a feature that is particularly valuable in applications requiring high mobility.

Thanks to a scientifically formulated material ratio and optimized structure, steel-aluminum telescopic guides exhibit excellent overall performance: they offer not only strong load-bearing capacity and excellent rigidity, but also excellent corrosion and wear resistance, enabling stable operation in a variety of complex environments. At the same time, its precision manufacturing process ensures smooth and accurate operation, low friction, and minimal noise, significantly improving the overall lifespan and operating efficiency of the equipment.

In terms of application, steel-aluminum telescopic guides are widely used in high-end fields such as industrial automation, precision instruments, medical equipment, rail transportation, aerospace, and defense. Whether for precise conveying and positioning, telescopic support for heavy equipment, or telescopic cabins in special environments and intelligent storage systems, they are core components for achieving structural expansion, precise displacement control, and efficient space utilization.

We provide comprehensive customized solutions based on your specific application scenarios and performance requirements, from material handling and structural design to load and travel configuration, to help your project improve reliability, reduce weight, and optimize space layout.